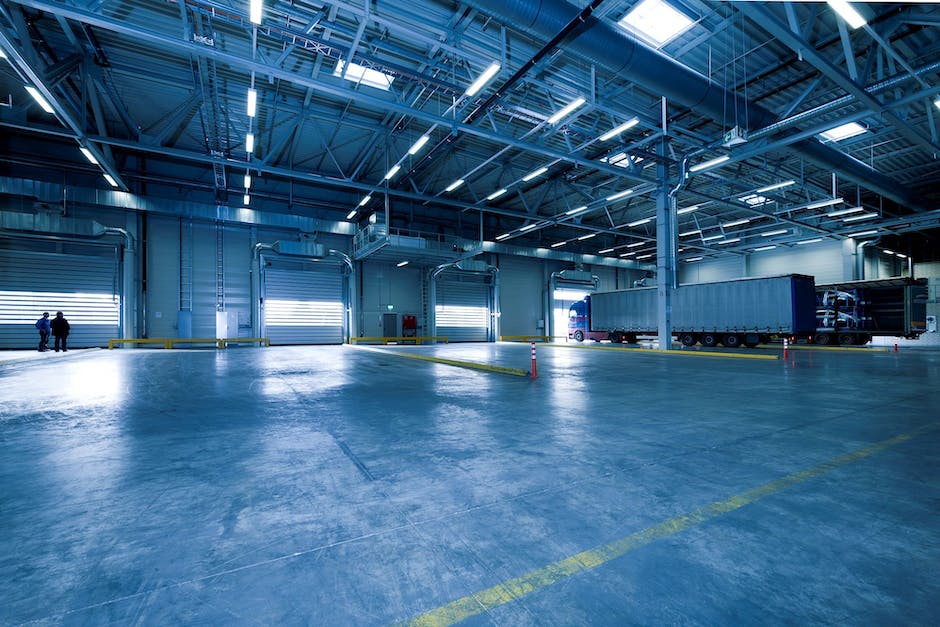

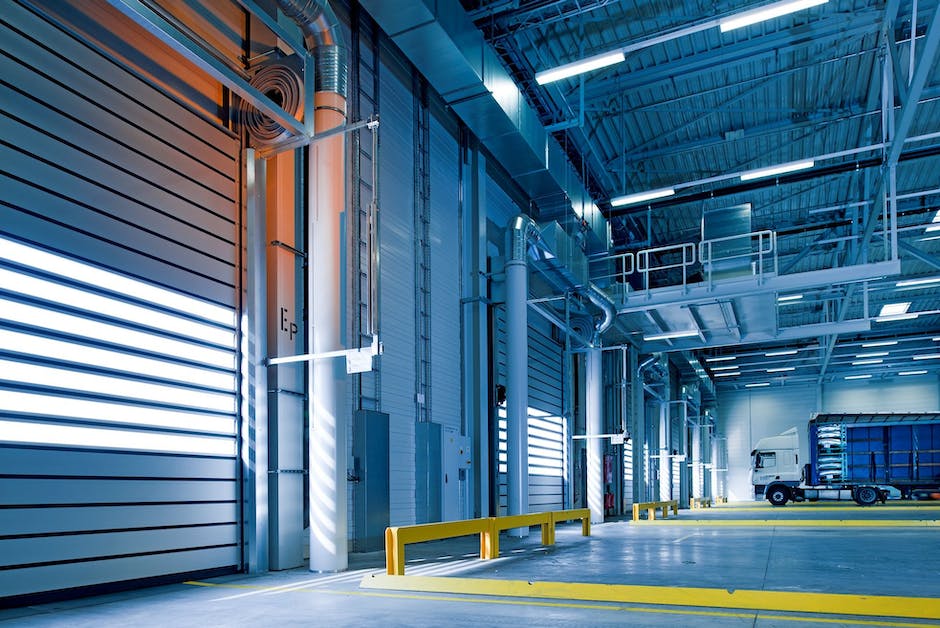

Introducing the Future of Warehouse Automation: Streamline Your Warehouse Processes with Fully Automated Systems

Are you looking to streamline and automate the operations in your warehouse? Then a fully automated warehouse system is your perfect solution. With the help of a powerful, comprehensive and automated system, you can monitor, track and manage your warehouse processes efficiently while minimizing operational costs. From inventory and order management to intelligent robots and improved safety and security, a fully automated warehouse system can offer a wealth of benefits that can help your business run smoother and more efficiently. Discover more about the advantages of such a system and why it is the right choice for your warehouse!

A fully automated warehouse system is a system that relies heavily on sophisticated robotic technology to move and store materials within a warehouse. This type of system is often used in places where automation can benefit from cost-savings, increased safety, increased accuracy and increased efficiency. With automation, there can be a reduction in labor costs, as well as a decrease in employee errors, which can create financial savings for the business. Additionally, an automated warehouse system can help prevent accidents that can cause injuries or fatalities, as well as help in the management of warehouse safety. In addition, the system can be programmed to carry out tasks continuously, ensuring a constant flow of materials into and out of the warehouse and eliminating delays that can occur with a manual system. Ultimately, a fully automated warehouse system can benefit a business by delivering improved quality and efficiency, while providing cost savings.

What are the benefits of using a fully automated warehouse system?

Automated warehouse systems are an invaluable tool for businesses, providing a suite of benefits to improve efficiency, accuracy, safety, and cost savings. As the demand for increased efficiency, accuracy and safety rises, automated warehouse systems can provide an effective solution. By automating labor-intensive tasks, businesses can reduce the time, labor and costs associated with storing, picking, and shipping goods. Furthermore, these systems can provide real-time, accurate inventory data, as well as reduce the risk of accidents and injuries associated with manual labor. Additionally, automated warehouse systems can be easily scaled to accommodate changing business needs, and adapted to meet the specific needs of different businesses. With these benefits, businesses can enjoy improved operational efficiency, accuracy and safety while reducing costs.

Automated warehouse systems provide numerous benefits to warehouses, from increased efficiency and accuracy to reduced costs and improved customer service. Automation can help streamline processes, reduce errors, and reduce the amount of time spent on manual labor. It can also help reduce costs associated with manual labor and the amount of space needed for warehouses. Automated systems can help improve safety by eliminating the need for manual labor and providing better monitoring and tracking of warehouse activities. Automation can also help improve customer service by increasing accuracy and speed of order fulfillment and delivery. All of these benefits of automation can help warehouses become more efficient, accurate, and cost effective while providing a better customer experience.

What are the benefits of using a fully automated warehouse system

Automated warehouse systems offer businesses a wide range of benefits, from increased efficiency and improved accuracy to reduced labor costs, improved safety, and scalability. Automated warehouse systems allow warehouses to quickly and accurately fulfill orders, leading to increased efficiency and productivity. By providing precise location tracking and inventory management, these systems reduce errors and improve accuracy. Automated warehouse systems also reduce the need for manual labor, resulting in significant cost savings. Additionally, they are designed to reduce the risk of human error and accidents, leading to a safer working environment. Finally, automated warehouse systems are highly scalable, allowing businesses to easily expand and adjust to changing demands. With these benefits, automated warehouse systems are becoming increasingly popular among businesses looking to save time, money, and optimize their operations.

Automated warehouse systems offer a wide range of benefits for businesses, from increased accuracy and efficiency to reduced costs and improved safety. With an automated warehouse system, businesses can reduce human error and increase accuracy by eliminating manual data entry and providing real-time visibility into inventory levels. Automated warehouse systems can also increase efficiency by reducing the time it takes to process orders, locate items, and move inventory. Furthermore, they can reduce the amount of labor needed to fulfill orders and manage inventory, resulting in increased productivity. Finally, automated warehouse systems can reduce costs associated with labor, inventory management, and other operational costs, allowing businesses to optimize their operations and save money. With these benefits, it’s clear that implementing an automated warehouse system can have an immediate and positive impact on a business’s operations.

What are the benefits of a fully automated warehouse system?

Automated warehouse systems provide a wide variety of benefits that can help to improve the efficiency of warehouses. By reducing the amount of manual labor required for warehouse operations, automated systems can help to reduce labor costs and improve customer service. Automated systems can also help to reduce errors and improve accuracy by using barcodes, RFID tags, and other tracking technologies. Additionally, automated systems can help to reduce the risk of accidents and injuries, as well as reduce operating costs by reducing the need for additional staff and reducing the time spent on manual processes. Finally, automated systems can be used to improve inventory management by providing real-time data and tracking of inventory levels, which can help to reduce overstocking and out-of-stock items. By taking advantage of these benefits, businesses can benefit from improved efficiency, accuracy, safety, and cost savings, making automated systems an invaluable asset to any warehouse.

Automated warehouse systems have become an increasingly popular solution for businesses looking to increase efficiency, reduce costs, and improve accuracy. From improved safety to scalability, automated systems offer a variety of benefits to warehouse operations. Increased efficiency is one of the main advantages of automated systems, as they are capable of quickly and accurately sorting and retrieving items, as well as managing inventory levels. They also help to reduce overhead costs associated with labor, as well as improve productivity and reduce the amount of space needed in a warehouse. Additionally, automated systems can help to improve accuracy by accurately tracking and recording inventory and order fulfillment, saving time and money on manual data entry. Finally, automated systems can help to reduce the risk of injury to personnel, as well as the risk of damage to goods and equipment, and can be easily scaled up or down to accommodate changing needs and demands. Through these benefits, automated warehouse systems are an ideal solution for businesses looking to maximize efficiency and minimize costs.

What benefits does a fully automated warehouse system provide?

Automated warehouse systems are becoming increasingly popular as they offer numerous benefits that can significantly increase efficiency, safety, scalability, and reduce costs. Leveraging these solutions can lead to faster order fulfillment due to eliminating manual processes, improved inventory accuracy, and reduced labor costs. This can also improve safety by eliminating manual labor and improving safety protocols, in addition to reducing the risk of theft or damage to inventory. Automated solutions allow businesses to scale their operations quickly to meet changing customer needs, helping them remain competitive and respond quickly to market changes. Furthermore, costs associated with labor, overhead, and inventory management are reduced, leading to increased profitability and better customer service. With these myriad benefits, it is no surprise why businesses are incorporating automated warehouse solutions into their operations.

Automated warehouse systems are becoming increasingly popular in the logistics sector and it’s easy to see why. They offer numerous advantages over traditional warehouse operations, such as increased efficiency, improved accuracy, cost savings, and improved safety. By streamlining processes, reducing manual labor, and eliminating the potential for human error, these systems can help to reduce the cost of warehouse operations and provide a faster, more accurate order fulfillment process. Automated systems also help to reduce the risk of accidents, improve safety, and provide a more reliable and efficient system for store inventory tracking. For businesses looking to cut costs and increase efficiency, investing in an automated warehouse system is a great way to achieve both goals.

What are the benefits of using a fully automated warehouse system

Automated warehouse systems can provide a range of benefits for businesses by greatly improving accuracy, efficiency, safety, scalability, and customer service. By implementing automated systems, businesses can realize cost savings on labor costs and improved productivity due to reduced errors. Additionally, the systems can help ensure that safety protocols are followed, allowing businesses to scale up quickly and easily while also providing improved customer service. By using customized HTML markdown and tables, businesses can easily present and track necessary data, enabling optimal reference and easy navigation of their warehouses. Automated systems help ensure that businesses remain competitive, constantly keeping up with industry trends and customer demands. In essence, automated warehouse systems are the backbone of modern warehouses, businesses, and customers alike.

The implementation of an automated warehouse system provides many benefits for any organization. From increased efficiency and cost savings to improved safety and customer service, automation can offer an array of advantages. Efficiency is improved through eliminating manual labor and manual data entry, which can lead to faster order processing and fewer errors. Automation can also reduce the labor costs, as well as the cost of materials, since fewer resources are needed to complete the tasks. As well, safety increases, as automated systems reduce the risk of human error and help to prevent workplace accidents. The scalability of automated systems allows for customization to meet the precise needs of a business as it grows, and customer service is enhanced as orders can be processed faster and more accurately. Finally, automation can help to improve inventory accuracy and reduce costs associated with inventory. All of these benefits make implementing a fully automated warehouse system a smart choice for any business.

What are the benefits of implementing a fully automated warehouse system?

Automated warehouse systems are a great way to improve efficiency, accuracy, productivity, and safety while reducing operating costs. By streamlining processes, eliminating manual errors, providing traceability, and reducing time it takes to complete tasks, automated warehouses are capable of significantly increasing productivity while reducing operating costs and labor costs. Additionally, automated warehouse systems enable businesses to easily scale up or down as needed to handle fluctuating demands, providing businesses with the flexibility to meet changing needs without having to invest in additional resources. Furthermore, automated warehouses ensure proper safety by taking over manual tasks which can increase the risk of accidents and injuries due to manual labor. With the ever-growing demand for warehouses, utilizing an automated system to manage inventory, orders, and shipments is the best way to ensure maximum efficiency, accuracy, and scalability.

Benefits of using a fully automated warehouse system can be seen in the table below. Those who are considering such a system should carefully consider the benefits and costs to ensure they find the right solution for their business.

| Benefit | Description |

|---|---|

| Accuracy & Efficiency | Robotics and automated conveyer systems reduce errors and improve accuracy |

| Inventory Management | Track and monitor inventory levels in real time for greater visibility and control |

| Safety | Reduced risk of accidents and theft |

| Cost Savings | Reduced labor costs, storage, transportation and energy costs |

Overall, the main benefits of using a fully automated warehouse system include improved accuracy and efficiency, better inventory management, enhanced safety, and significant cost savings. Automated warehouses can help businesses be more efficient and save money in the long run, making them a great option for many businesses.

What benefits does a fully automated warehouse system provide

An automated warehouse system provides numerous benefits, ranging from increased accuracy and efficiency to improved safety and reduced operating costs. Automation can also facilitate scalability and provide a platform to enhance customer service by providing relevant real-time insights that can be used to increase order accuracy and reduce order lead times. Furthermore, it eliminates the need for manual labor which increases safety, as well as decreasing costs associated with labour, management and maintenance. With the help of automated systems, warehouses can improve their operational performance across the board, leading to improved customer satisfaction and increased revenue. Additionally,automated systems can be used to facilitate the tracking and monitoring of inventory levels,delivery times and stock levels to ensure that orders are fulfilled in the most efficient manner. As a result, an automated warehouse system can significantly improve warehouse efficiency, customer service and ultimately profitability.

Automated warehouse systems can make businesses more efficient, accurate, cost-effective, and safe. Through the use of robotics and other advanced technologies, these systems provide improved capabilities that increase efficiency, accuracy, scalability, and safety. With increased efficiency, warehouse operations are able to run faster and more accurately while optimizing resources. This helps to reduce costs while increasing the speed and accuracy of order fulfillment. Additionally, automated warehouse systems allow businesses to easily scale up or down as needed, allowing them to better adjust to changing inventory levels. Not only do automated warehouses eliminate the need for manual labor, they also reduce the potential for human error, improving overall safety. By utilizing automated warehouse systems, businesses can achieve greater efficiency, accuracy, cost savings, and improved safety.

What are the benefits of using a fully automated warehouse system?

By implementing an automated warehouse system, businesses can enjoy many benefits, including improved accuracy and efficiency, improved safety, lower operating costs, improved customer service, and increased scalability. This advanced technology is incredibly valuable for modern warehouses, as it helps them keep up with the ever-changing needs of a competitive market. Additionally, automated warehouse systems provide flexible solutions to warehouse needs, allowing warehouses to quickly and easily adapt to new situations. Ultimately, businesses that choose automation solutions are highly likely to improve overall performance and remain competitive in the long term.

Automated warehouse systems are revolutionizing modern warehouse operations. Automation offers many beneficial advantages, from increased efficiency and improved accuracy, to cost savings and increased productivity. These advantages ultimately lead to an improved bottom line for warehouse operators. Automated systems can help reduce labor costs and eliminate the need for manual labor, allowing warehouse operations to operate at faster speeds with increased accuracy and safety. Furthermore, automated systems can help track and record inventory levels and movement more accurately, leading to better monitoring and improved inventory control. Automation can also reduce overhead costs and help warehouses process orders more quickly and accurately, allowing them to fulfill more orders in a shorter period of time. All of these advantages ultimately lead to improved efficiency and cost savings, resulting in better overall performance.

Final Words

An automated warehouse system is a system that enables a warehouse to be operated entirely through technology and automation, meaning the system both manages and controls the movement of goods and inventory in a warehouse. The system typically uses robots, automated conveyor belts, ASRS systems, and sensor technology to manage the flow of goods and inventory in a warehouse space. Automated warehouse systems often reduce the number of manual workers needed to manage a warehouse and increase storage capacity, efficiency and accuracy.

FAQ About Fully Automated Warehouse Systems

- What is a fully automated warehouse system?

A fully automated warehouse system is an inventory management solution that utilizes robotic technologies to automate the process of stocking, unpacking, and storing items. Automated warehouse systems are capable of performing tasks quickly and efficiently without the need for manual labor. - What are the benefits of using a fully automated warehouse system?

The primary benefit of using an automated warehouse system is increased efficiency and cost effectiveness. Automated systems are capable of carrying out tasks more quickly and with fewer errors than manual labor. Additionally, automated warehouse systems can save businesses money by reducing labor costs and improving the accuracy of inventory tracking. - What types of businesses are best suited for a fully automated warehouse system?

Fully automated warehouse systems are an ideal choice for businesses that need to manage large inventories or ship orders quickly and accurately. Warehouses and e-commerce businesses typically benefit the most from the efficiency of automated systems. - Are there any potential drawbacks to using a fully automated warehouse system?

The primary potential drawback of using a fully automated warehouse system is the cost associated with purchasing and maintaining the system. Automated systems can be expensive to initially purchase and may require ongoing maintenance to ensure optimal performance.

Conclusion

Fully automated warehouse systems can provide businesses with increased efficiency and cost effectiveness while reducing labor costs and improving the accuracy of inventory tracking. Automated systems are an ideal choice for warehouses and e-commerce businesses, but can be expensive to initially purchase and require ongoing maintenance to ensure optimal performance. With careful research and the right integration plan, a fully automated warehouse system can have an invaluable impact on your business.